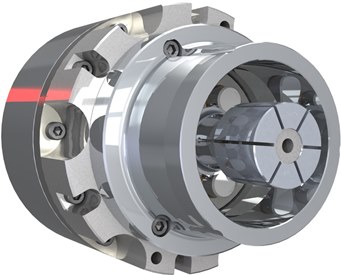

Mandrelsystem MIS

For the internal clamping a mandrel is often the best solution. Therefore we have developed in addition to our diaphragm chuck line a mandrel system which offers many advantages.

Ideal fit the MIS mandrels system to all diaphragm chucks size 150. The operation of the diaphragm chuck and thus the mandrel system can be pneumatic or power operated.

The adaption to different chuck sizes there are mandrel adaptations available. Further it is possible, to convert to an outside clamping very easily with a diaphragm clamping set.

The modular design results at moderate prices with maximum flexibility.

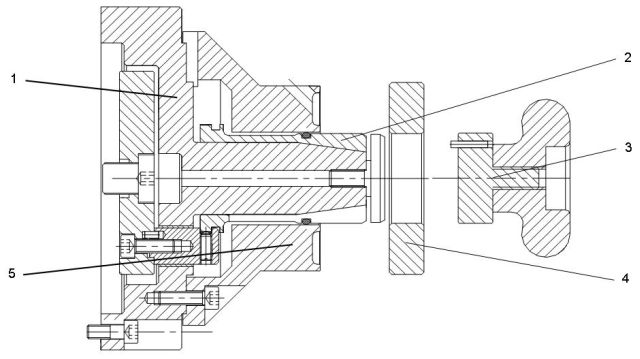

The MIS mandrel system consists of the assemblies base mandrel, clamping set and workpiece stop. A clamping set consists of collet, master ring and Changing fixture. With the system clamping diameters between 20 and 121 mm are realizeable.

The base mandrels have for mounting on the chuck a pilot for chuck size 150 incorporated. By centering a faster and more accurately changeover to other mandrel sizes is possible. Each base mandrel covers a clamping range of at least 5 mm.

With a changing fixture collets engages at a bayonet lock into the base mandrel. Similar clamping diameters are installed within seconds.

By on the base mandrel mounted part stops, a precise axial workpiece positioning is secured.