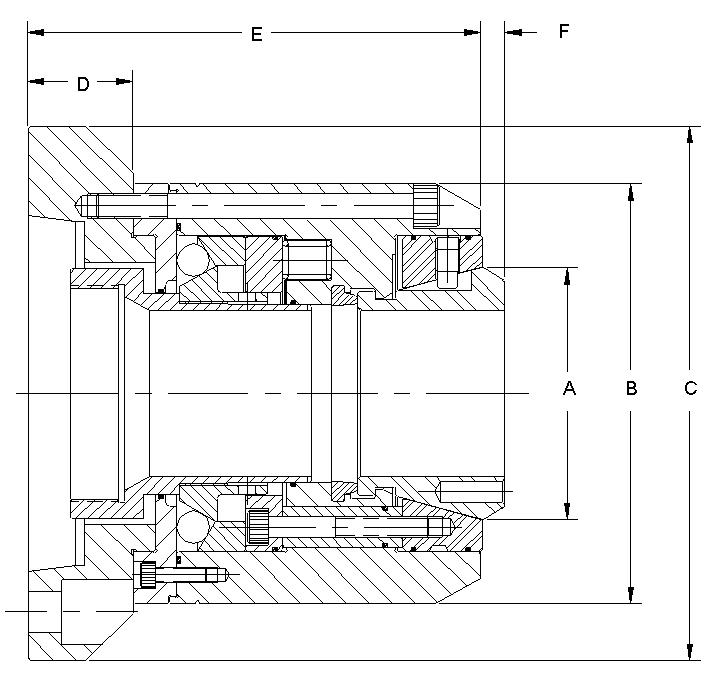

Quick change collet chuck CB-NDR, axially fixed collets on pull

At the chuck series CB-NDR the collets are engaged in a coupling in the chuck body. Through the backward movement of the drawtube the sliding sleeve with a cone is moving forward by a patented system. Thereby the radial clamping movement is performed without the pull down effect of the workpiece.

Optional an axially fixed workpiece stop can be installed in the chuck from the front. Because of that this series can be used for bar and chuck work.