Bearing race

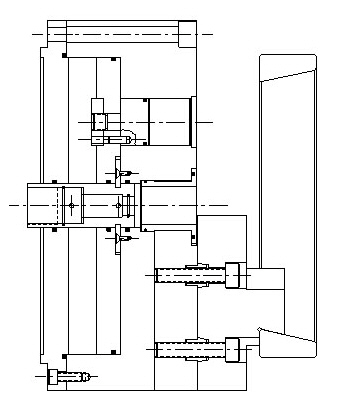

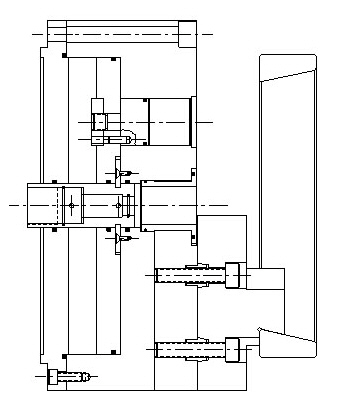

A family of bearing races are to be chucked on a tapered ID to finish turn the OD and face the workpiece.

A large travel chuck is required to overcome inside diameter variations during loading and unloading. Top jaw changeover time is to be minimized while maintaining required concentricity and roundness specifications.

Required accuracy: 0,005 mm TIR

A 250 mm air chuck with 10 mm total jaw stroke was supplied to permit loading and unloading of the workpieces. The workholding system also included a series of hardened and ground QC top jaws to chuck the tapered ID of the workpiece, and located on the rear face. Jaw width is maximized to distribute chucking force and reduce workpiece distortion to maintain workpiece roundness.

Achieved accuracy: 0,004 mm (incl. changeover)