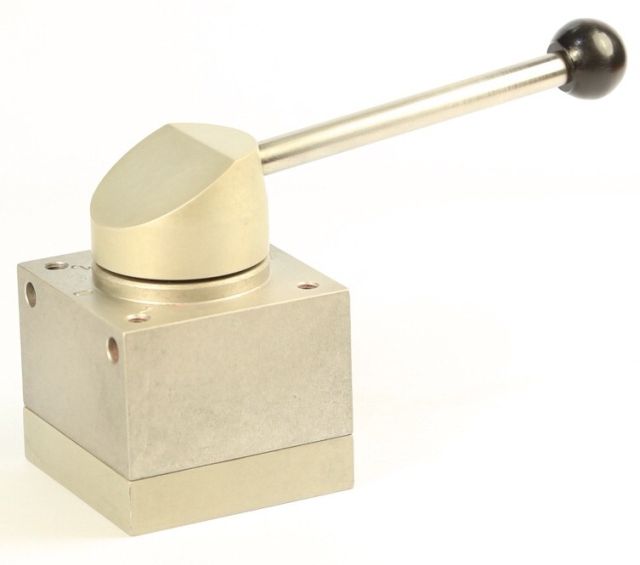

Control units

For comfortable activation of the pneumatic a control unit could get used. There are several different versions.

The control unit BE-2 has a coupling to accept standard workshop air supply. Also supplied are fittings for connection to the MicroCentric air tubes. For opening the chuck one manometer and one air control valve are used, and a second pair for closing the chuck. Therefore chucks can be opened & closed using independant air pressure, opening and closing is easily done by push-bottons. Inside of the control unit cabinet is a hand operated valve, which is used for the disconnection of air pressure and for changeing the opening and closing lines.

With the unit BE-3 it is possible, to control a pneumatic air cylinder in addition to the functions of unit BE-2. This is a solution for machines using power operated collets and pneumatically operated chucks built in. With unit BE-3 the changeover time will be minimized, in addition to the BE-2 the BE-3 has a second built in hand operated control valve.

Control unit BE-4 has in addition to unit BE-2 a second air pressure control for closing the chucks. This allows chucks, (especially diaphragm chucks), to be operated with 2 different air pressures for example, with higher clamping force for rough machining and lower clamping force for finish machining. Additionally the BE-4 has a further manometer, air pressure valve and push-button built in.

Other control units for the activation of clamping systems (for example: electro-pneumatic off SPS-interface) available on request.

| Order No. |

Designation |

Usage for: |

| BE-2 |

Control unit BE-2 |

Sizes 75-400 |

| BE-3 |

Control unit BE-3 |

Sizes 75-400 |

| BE-4 |

Control unit BE-4 |

Sizes 75-400 |